6 Sustainable Building Materials Revolutionising Construction in Melbourne

)

In Melbourne, a sustainable construction revolution is underway, where innovative materials are reshaping the cityscape with both style and environmental consciousness.

As climate change intensifies and resources dwindle, the demand for sustainable building materials has surged. Melbourne, known for its architectural diversity, stands at the forefront of this movement, integrating eco-friendly alternatives into its structures.

From Cross Laminated Timber at Forte, one of the world’s tallest timber buildings, to cutting-edge research on Cigarette Butt Bricks at the Royal Melbourne Institute of Technology, these materials are not just changing the city's skyline but also setting a global standard for environmentally responsible construction practices. This article explores six pioneering materials that are not only enhancing Melbourne's urban landscape but also championing a greener, more sustainable future for the construction industry.

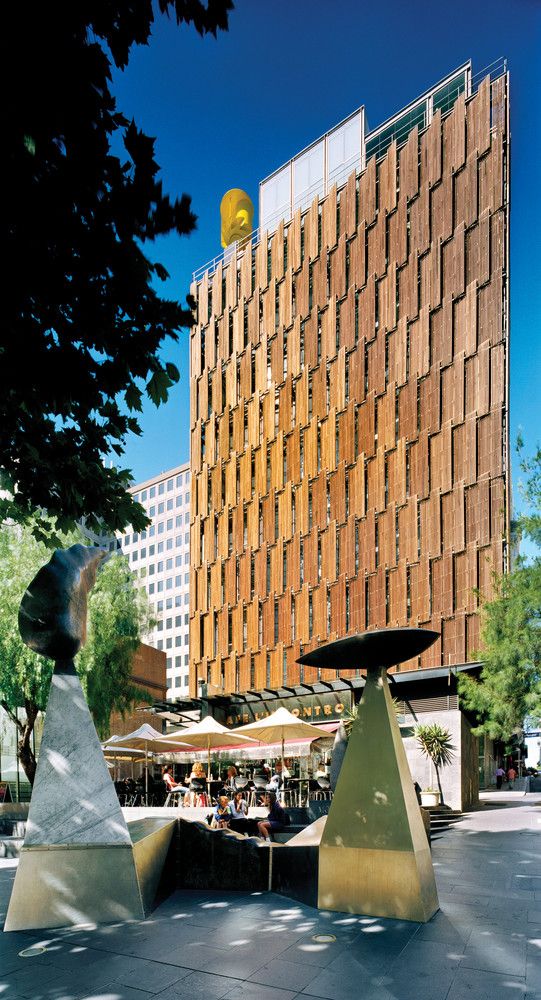

1. Cross Laminated Timber (Forte Living)

Starting with Melbourne’s Forte Living apartment building in Docklands, it was Australia's first mass-timber high-rise apartment building, which was built from cross-laminated timber (CLT). Forte held the title of the world’s tallest timber residential building, at 32 meters tall, when it was constructed in 2012.

Crafted from 759 CLT panels made from European spruce harvested in Austria by manufacturing company KLH, Forte stands as a testament to sustainable construction practices. Once harvested, the timber was transformed into CLT at KLH's Austrian factory before being flat-pack shipped to Australia. It was designed to demonstrate the potential of utilising CLT in Australia, despite the material not being locally sourced.

Lendlease, at the time of completion, highlighted the significance of this achievement, stating Forte is "a showpiece for natural and new, it is where modern architecture meets a natural building material, called cross-laminated timber (CLT), which will unlock a new era in the future of sustainable development and healthier living". This pioneering use of CLT in the Forte building marked the beginning of a transformative journey towards recognising the vast potential of this revolutionary material in the local market. It showcased that sustainable construction can be both environmentally conscious and also visually impressive.

CLT now stands at the forefront of sustainable construction materials, offering a multitude of environmental benefits. As a renewable resource, CLT reduces reliance on finite materials like concrete and steel, leading to lower carbon emissions and a smaller ecological footprint. Its manufacturing process sequesters carbon dioxide, contributing to a net reduction in greenhouse gases. Additionally, CLT's prefabricated nature enables efficient construction, minimising waste and on-site disruptions while promoting energy efficiency in buildings. This innovative material not only exemplifies sustainable development but also paves the way for a greener and more eco-conscious future in Australian construction practices.

2. Low-carbon Concrete (60L & Pixel)

Moving from CLT to another sustainable alternative to traditional concrete, low-carbon concrete offers a solution to the environmental challenges posed by Portland cement. Concrete, a notably carbon-intensive material globally, accounts for nearly six percent of the world's annual greenhouse gas emissions.

In response to this issue, Melbourne’s construction industry is coming up with innovative low-carbon concrete. The concrete used for 60L, the premier green commercial building in Australia located in Carlton, contains about 60% recycled material, such as aggregate and fly-ash.

![]() Similarly, Grocon's project team, working on the Pixel, Carlton, collaborated with Boral Concrete for a year to develop a new structural concrete solution with reduced embodied carbon and a focus on recycling. The outcome, 'Pixelcrete,' is an innovative concrete mix that utilises 60% less cement and incorporates 100% recycled and reclaimed aggregate.

Similarly, Grocon's project team, working on the Pixel, Carlton, collaborated with Boral Concrete for a year to develop a new structural concrete solution with reduced embodied carbon and a focus on recycling. The outcome, 'Pixelcrete,' is an innovative concrete mix that utilises 60% less cement and incorporates 100% recycled and reclaimed aggregate.

Howard Titus, Grocon's National Manager Concrete Technology, noted that "up to 92% of the weight of the concrete is industrial waste, recycled or reclaimed material," showcasing a significant shift towards sustainability. Despite these changes, Pixelcrete maintains the same strength as traditional concrete and can be applied in various construction applications. Howard emphasised the versatility of Pixelcrete, stating, "We used Pixelcrete for the piles, groundworks, slabs, and columns," and highlighted the pioneering use of plasticised concrete for suspended post-tension slabs, marking a step forward in sustainable construction practices.

3. Recycled Rubber Tyre Flooring and Pavement (Yarra City Council Project & East Melbourne Library)

Innovative approaches to sustainable construction extend beyond structures to include recycled materials for flooring and pavement. Waste rubber tyres are finding new life through recycling initiatives, offering benefits for both pavement and indoor flooring projects.

For instance, Yarra City Council utilised half a tonne of Australian recycled tyres in a recent project to address surface heat concerns and improve urban tree health. Limited space for traditional water-sensitive urban design led the council to seek solutions that combat the urban heat island effect while enhancing green infrastructure.

At Rutland Street, Clifton Hill, the council piloted a new permeable pavement product made from recycled soft tyres bonded with a polyurethane binder. This innovative material not only reduces stormwater runoff to local drains and waterways, but it also withstands extreme weather events while providing better irrigation for street trees. The project, supported by Sustainability Victoria's Sustainable Infrastructure Fund, aims to assess the impact of permeable pavements on ambient temperatures, surface heat, tree health, water runoff, life-cycle performance, and maintenance requirements.

The project, supported by Sustainability Victoria's Sustainable Infrastructure Fund, aims to assess the impact of permeable pavements on ambient temperatures, surface heat, tree health, water runoff, life-cycle performance, and maintenance requirements.

In another eco-friendly application, the East Melbourne Library opted for indoor flooring crafted from granules and recycled car tyres. The utilisation of recycled tyres in flooring products not only diverts waste from landfills but also reduces the demand for virgin materials, contributing to resource conservation and environmental sustainability. This approach showcases a circular economy model where waste materials are repurposed into valuable products, mitigating the environmental impact of tyre disposal and fostering a more sustainable construction industry.

4. High-performance film (East Melbourne Library)

The East Melbourne Library incorporates yet another environmentally conscious building material in the form of high-performance films applied t o its glass façade. The implementation of high-performance films on the glass façade serves as a strategic solution to mitigate heat transference within the building.

o its glass façade. The implementation of high-performance films on the glass façade serves as a strategic solution to mitigate heat transference within the building.

By selectively filtering out infrared radiation and UV rays, these films help regulate indoor temperatures, reducing the need for energy-intensive mechanical heating and cooling systems that contribute significantly to carbon emissions. This innovative technology enhances energy efficiency, fostering a more sustainable approach to building climate control. Additionally, it creates a more comfortable indoor environment for occupants by minimising glare and maintaining a consistent temperature throughout the structure.

5. Low-VOC paints and sealants (Council House 2)

When considering sustainable building practices, one crucial aspect to address is the indoor air quality, which significantly impacts both the environment and occupant well-being. An essential strategy employed in this regard is the use of materials with low volatile organic compound (VOC) emissions, as exemplified by Council House 2 (CH2) in Melbourne.

VOCs are chemicals that can vaporise and negatively impact indoor air quality and the environment. High levels of VOCs can lead to various health issues and contribute to air pollution and ozone formation. To address these concerns, CH2 implemented strategies to enhance indoor air quality, including the use of materials with low VOC emissions.

CH2 prioritised indoor environment quality as a key focus during its design phase, aiming to create a healthy, comfortable, and stimulating work environment for occupants. To achieve this goal, CH2 employed materials known for emitting low levels of volatile organic compounds, including low-VOC paints, carpets, adhesives, and sealants. These choices not only improved the indoor air quality but also contributed to the overall well-being of occupants, potentially resulting in fewer sick days and increased productivity. By implementing these sustainable practices, CH2 not only created a healthier workspace but also demonstrated a commitment to environmental responsibility and employee satisfaction.

CH2 prioritised indoor environment quality as a key focus during its design phase, aiming to create a healthy, comfortable, and stimulating work environment for occupants. To achieve this goal, CH2 employed materials known for emitting low levels of volatile organic compounds, including low-VOC paints, carpets, adhesives, and sealants. These choices not only improved the indoor air quality but also contributed to the overall well-being of occupants, potentially resulting in fewer sick days and increased productivity. By implementing these sustainable practices, CH2 not only created a healthier workspace but also demonstrated a commitment to environmental responsibility and employee satisfaction.

6. Cigarette Butt Bricks (RMIT)

Reducing the carbon footprint in construction entails embracing innovative recycling strategies. As highlighted earlier, tyres constitute a significant waste product in Australia, finding new life as components in concrete and flooring. Building upon this sustainable trend, researchers at the Royal Melbourne Institute of Technology (RMIT) have explored the concept of recycling cigarette butts to create bricks.

Cigarette butts, the most commonly discarded single waste item globally, possess materials that can be repurposed to create lightweight bricks with reduced energy consumption and improved thermal properties. The project lead by Associate Professor Abbas Mohajerani and students at RMIT University showcases the potential benefits of incorporating cigarette butts into brick manufacturing processes, highlighting the importance of sustainable waste management practices in the architectural realm. The study found that integrating cigarette butts into bricks could significantly decrease energy requirements during firing, leading to substantial energy savings and reduced environmental impact in the brick manufacturing industry.

The Melbourne-based study also highlighted the complexities of adding cigarette butts to clay bricks for architectural use. While this innovative approach shows promise in reducing energy consumption and enhancing the thermal properties of bricks, challenges such as addressing bacterial contamination and potential health hazards need careful consideration before widespread implementation. By embracing unconventional sources of raw materials and promoting sustainable practices, initiatives like these not only offer a pathway to more environmentally conscious construction practices but also underscore the importance of creative solutions in tackling waste management and resource efficiency in the architecture and building industry.

The Melbourne-based study also highlighted the complexities of adding cigarette butts to clay bricks for architectural use. While this innovative approach shows promise in reducing energy consumption and enhancing the thermal properties of bricks, challenges such as addressing bacterial contamination and potential health hazards need careful consideration before widespread implementation. By embracing unconventional sources of raw materials and promoting sustainable practices, initiatives like these not only offer a pathway to more environmentally conscious construction practices but also underscore the importance of creative solutions in tackling waste management and resource efficiency in the architecture and building industry.

Melbourne emerges as a vanguard of sustainable construction practices, where a wave of eco-conscious innovation is reshaping the cityscape. From new concrete inventions to recycled tyre flooring, Melbourne showcases a commitment to integrating environmentally friendly materials into its architectural fabric. By leading the charge in adopting sustainable building solutions, the city not only transforms its skyline but also sets a global benchmark for responsible construction practices. Melbourne's dedication to sustainability not only enhances the urban environment but also underscores the crucial role of innovative materials in steering the construction industry towards a more environmentally conscious and resilient future.

Melbourne Build is the leading and largest construction trade show for Melbourne and Victoria, taking place October 22nd & 23rd 2025 at MCEC. Featuring two jam-packed days of knowledge-sharing, 450+ expert speakers across 7 conference stages, a 300+ booth exhibition, Meet the Buyers, business networking, live music, entertainment and so much more! Don’t miss out on free tickets.